Informational content provided by Jamie at ImmersionHeaters.uk.

For the full shilling version, see the web authority on everything, Wikipedia, or an informative, if uninspiring, site referenced on the wiki page.

The extremely abridged version – its an electrically powered tube which applies direct heat to liquids and gases.

And finally, the Immersion Heaters UK version. Here is one I chopped up earlier –

Video for those that are allergic to reading.

The top end is the terminal, sometimes a spade connection, but more usually a thread, washer and bolt combination, geared at holding the electrical connection, ie, incoming wire, in place.

Below the nuts is a white plastic plug which serves as a seal against ingress of moisture and also to hold all of the important bits inside in the middle of the tube, away from the sheathing.

The sheathing material is the outer housing, the solid casing, usually made of a metal, in this case Incoloy 800, a stainless steel variant. This serves to encase and protect the important bits, protecting them from whatever is being heated, ie, oils, chemicals, etc.

The white compacted powder inside the tube is magnesium oxide powder, which serves as an insulator against electrical leakage, but as a conductor of the heat generated by that electrical current. It serves to hold the filament wire centrally within the tube so that contact with the sheathing material is all but impossible.

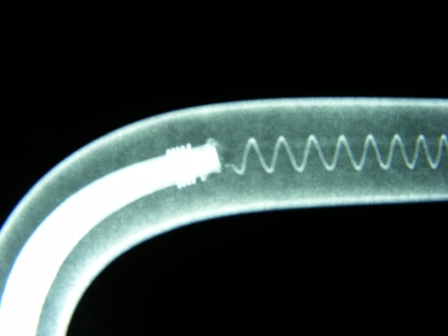

Finally, the tiny wire seen protruding at the bottom of the picture is the filament wire which creates the heat in the core of the element. Usually Nickel Chromium, this converts electricirty very efficiently into heat, with only a little wastage as light, as with the filament of an old light bulb. Whilst it is straight in the picture above (due to being hacksawed), under normal circumstances it would be coiled centrally in the magnesium oxide, as shown below, in this very cool x-ray.

The picture above also helps to explain the terms cold end, cold section, dead length, etc. The bit before the wiggly filament, that looks a bit like a hose pipe, is the other end of the terminal pin, the nuts & washers electrical connection as described above. Usually mild steel, this section is not going to create a great deal, if any heat, and so this is termed the cold section. All elements have two terminals, one at either end, to complete an electrical circuit, and both ends will have a cold section of 2 – 6″ dependent on the application.

This length would have to be subtracted from the element length when calculating watts density, ie, a 48″ 1000W element with 6″ colds has only 36″ active length (48″ – 6″ – 6″ = 36″), so the watts density of this element is 1000 / 36 = 28w/in².

So that is a plain heating element, but what about finned heating elements?

Mainly for use in air duct heaters, finned heating elements are merely plain elements as detailed above, but with finning added by a very clever machine.

This allows for better dispersion of the heat, basically by creating more surface area of heated element in the same available space.

Thanks for your interest. Any comments, feedback, additional information, please feel free to contact Jamie via our website..